Lens materials for prescription safety spectacles

Due to the wide range of applications that lenses have, the materials used need to fulfil a variety of requirements. To stay true to our motto #protectingpeople, we make sure to offer a wide selection of different lens materials. This selection ranges from highly scratch-resistant and chemical-resistant materials to impact-resistant plastics and designs with special filter effects.

Applications for prescription safety spectacles

The table below provides an overview of our range of lens materials and potential applications, giving a suitability assessment for each one.

5 points = optimal / 0 points = not suitable

| 1.59 Polycarbonate | 1.53 Trivex | 1.50 CR39 | 1.6 High Index | 1.67 High Index | 1.52 Hard Glass | |

|---|---|---|---|---|---|---|

| EN 166 certification marking | 2C-1.2 W 1 FT CE | W 1 FT CE | W 1 S CE | W 1 S CE | W 1 S CE | W 1 S CE |

| Applications | ||||||

| Turning / Milling | ||||||

| Laboratory work | ||||||

| Grinding / Dust work | ||||||

| Acid / Electroplating | ||||||

| Work with chemicals | ||||||

| Painting work |

Mechanical strength

Individually manufactured uvex prescription safety spectacles are tested and certified by independent testing institutes at regular intervals in accordance with the applicable eye protection standard. The principal requirement for this standard is mechanical strength. This requirement is broken down into different strength categories:

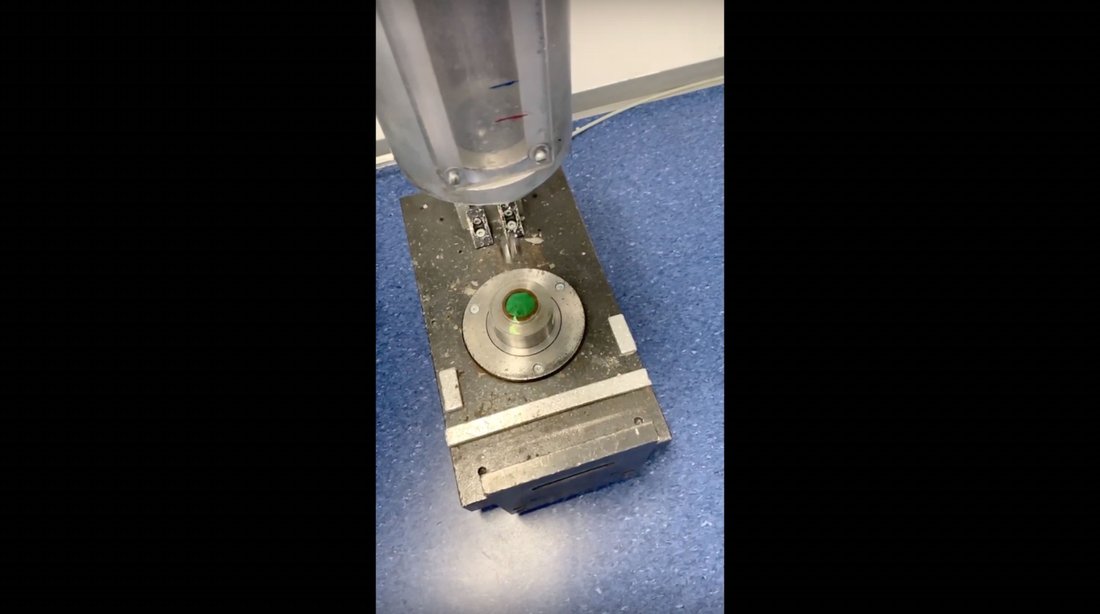

S – Increased robustness: ball bearing drop test, dropping a steel ball (44 g) onto the lens from a height of 1.30 m

Available lens materials: CR39, HI 1.6, HI 1.67, Hard Glass

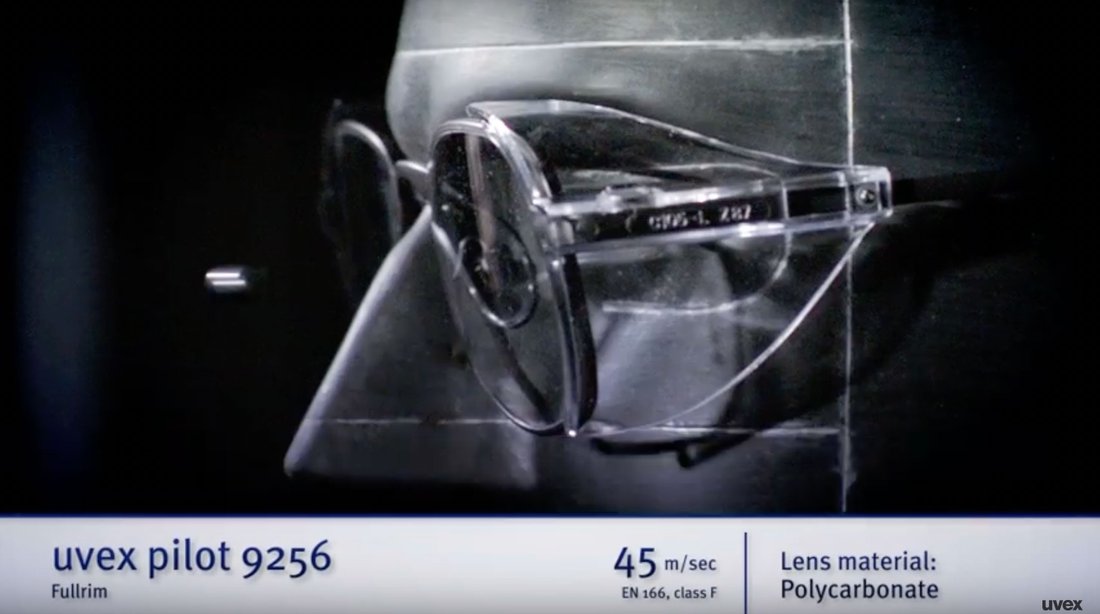

F – Impact-resistant, low energy impact: firing a steel ball (0.88 g) at the lens, with an impact speed of 45 m/s (≙ 162 km/h)

Available lens materials: Polycarbonate (PC), TrivexTM

B – Impact-resistant, medium energy impact: firing a steel ball (0.88 g) at the lens, with an impact speed of 120 m/s (≙ 432 km/h)

Available lens materials: PC+

Ball bearing drop test – mechanical strength S

The following lens materials have been tested and certified in accordance with the category S mechanical strength test: CR39, HI 1.6, HI 1.67, Hard Glass

Ball bearing firing test – mechanical strength F

The following lens materials have been tested and certified in accordance with the category F mechanical strength test: Polycarbonate (PC), TrivexTM

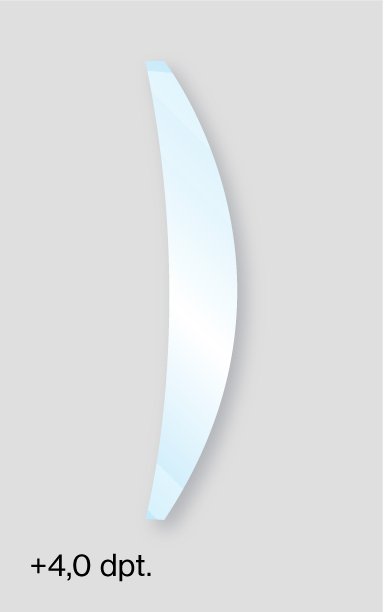

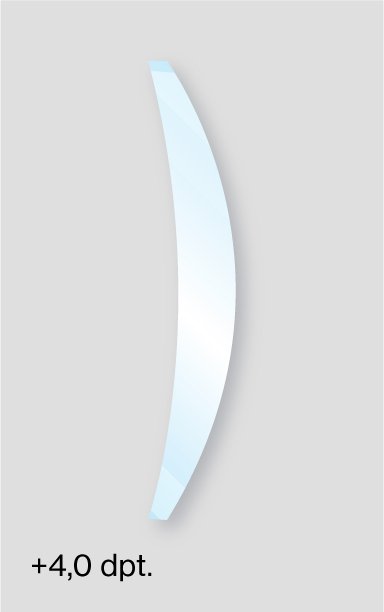

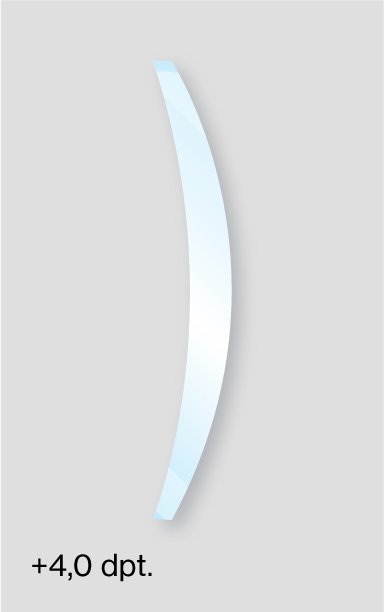

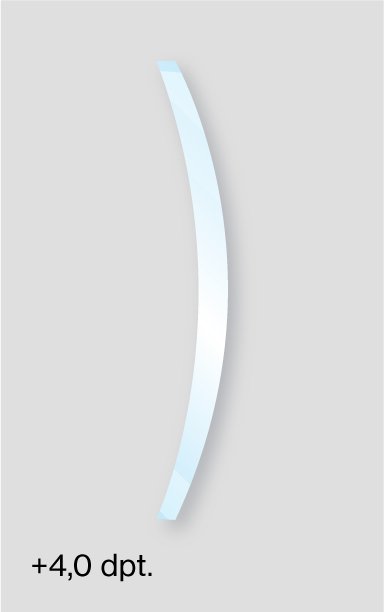

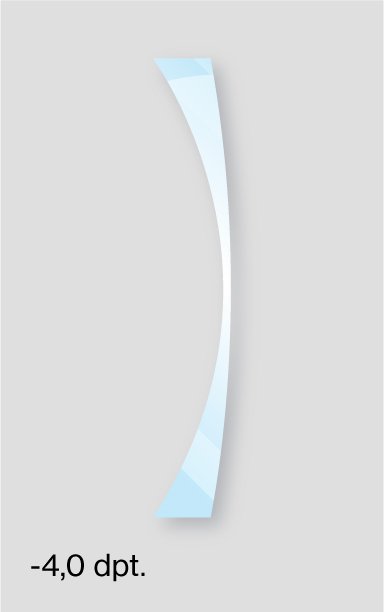

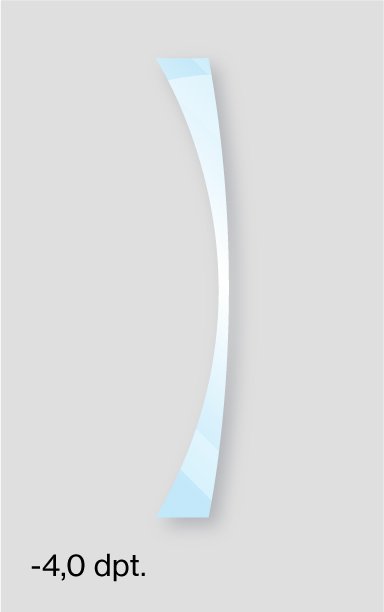

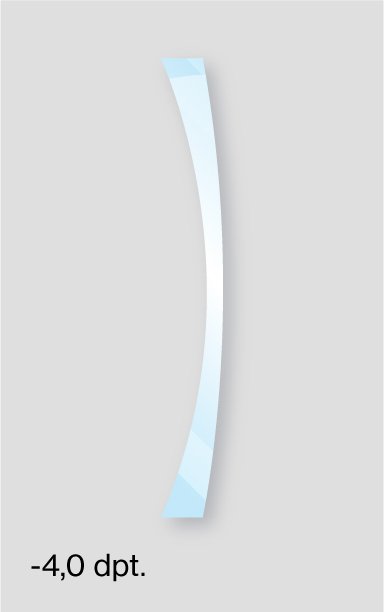

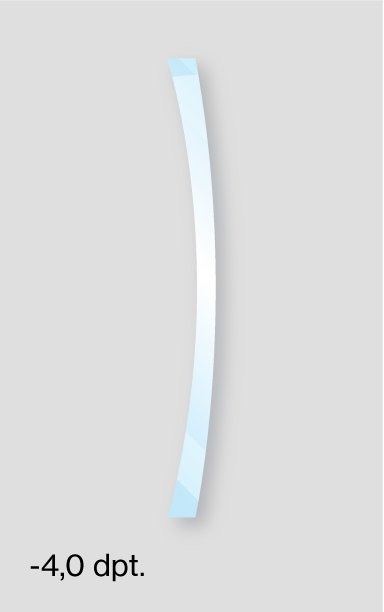

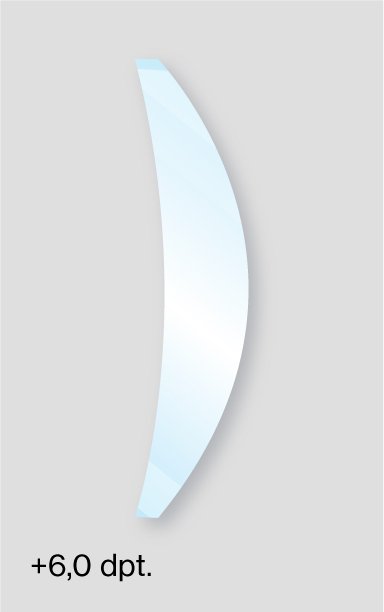

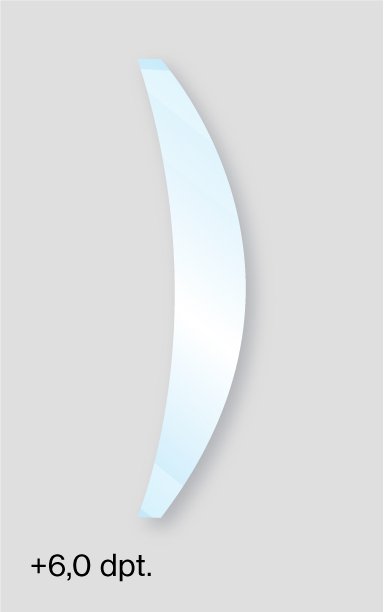

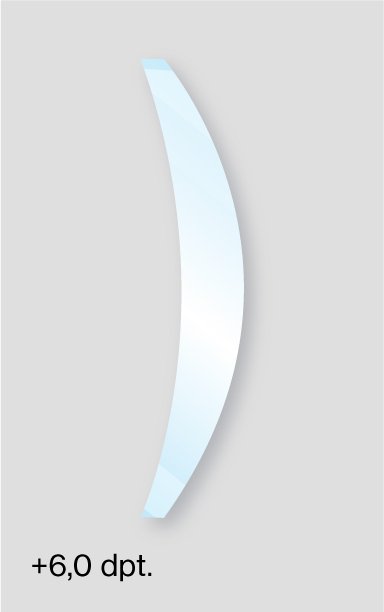

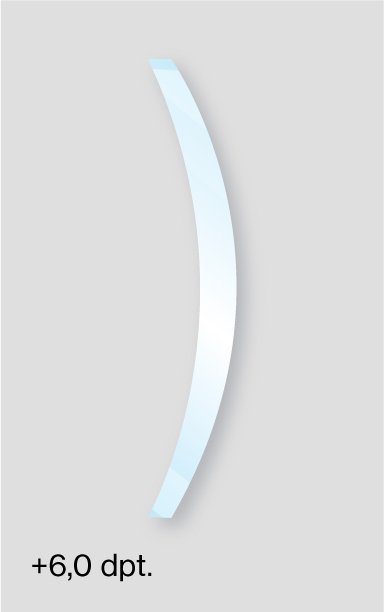

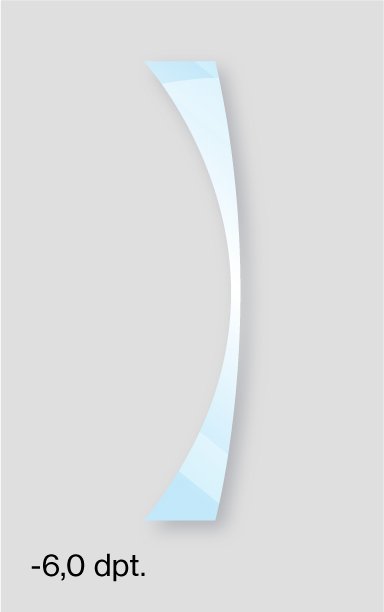

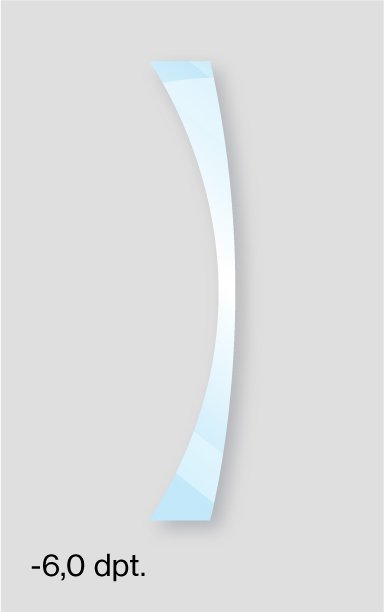

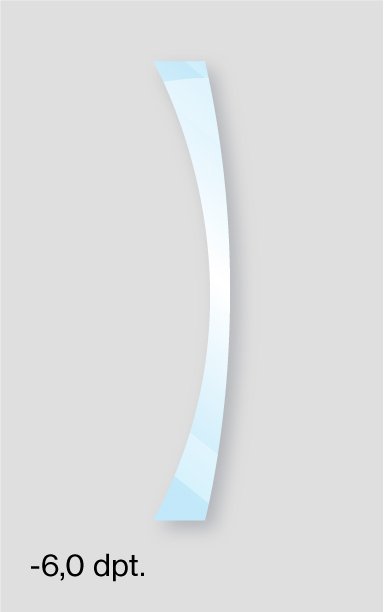

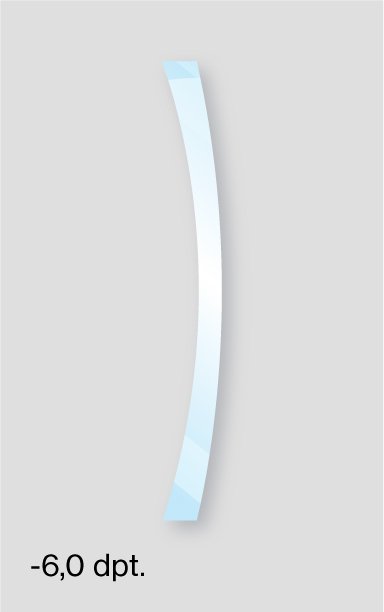

Refractive index

The higher the refractive index of a lens (e.g. 1.67), the thinner, lighter and more attractive the lens for an equal dioptre.

- High Index Plastic (HI) 1.67

- High Index Plastic (HI) 1.6

- Polycarbonate 1.59

- Trivex 1.53

- Hard Glass 1.52

- CR39 1.50

Direct comparison

CR39 1.5

TrivexTM 1.53

Polycarbonate 1.59

High Index 1.6

High Index 1.67

CR39 1.5

TrivexTM 1.53

Polycarbonate 1.59

High Index 1.6

High Index 1.67

CR39 1.5

TrivexTM 1.53

Polycarbonate 1.59

High Index 1.6

High Index 1.67

CR39 1.5

TrivexTM 1.53

Polycarbonate 1.59

High Index 1.6

High Index 1.67

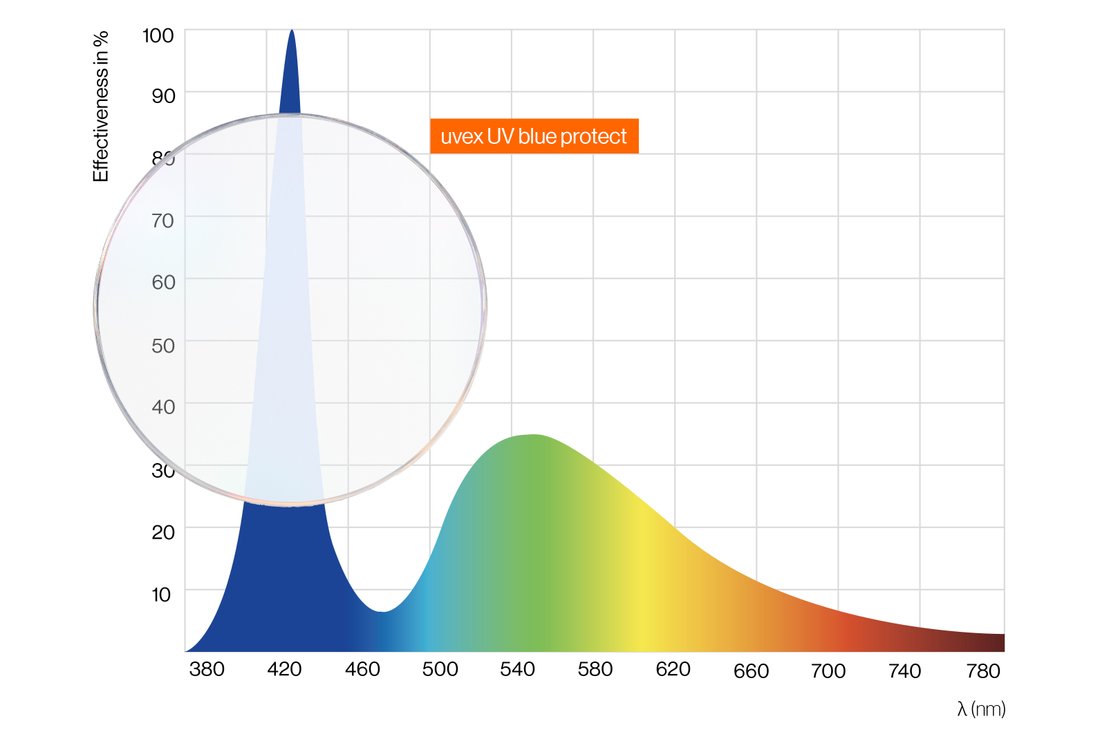

uvex UV blue protect

A special absorber has been added to the lens material that completely filters out UV rays and reduces the blue light content.

- The lenses absorb 100% of UV radiation up to 400 nm, almost completely filter short-wave blue light up to 410 nm and reduce the spectrum from 410 nm to 420 nm by 86%

- uvex UV blue protect lenses enhance contrast and effectively prevent signs of fatigue and age-related macular degeneration (AMD)

- uvex UV blue protect is optionally available for Polycarbonate (PC) and HI 1.67 lenses

- The mechanical strength of the lenses is guaranteed – clear lenses with UV blue protect are marked 2C-1.2 according to EN 170

Prescription safety spectacles – available models

When it comes to eye protection, uvex makes no compromises and offers reliable protection in the form of individually adapted safety spectacles. Our diverse collection means you can be sure that uvex will have the perfect prescription safety spectacles for each and every one of your employees.

Find a uvex individual personal protective equipment partner near you

Our close-knit network of highly qualified optics, acoustics and orthopaedics experts ensures the availability of first-rate uvex quality of care in your area. You can therefore always rely on short supply routes, perfectly fitted individual personal protective equipment products and optimal protection.

uvex sportstyle RX – prescription sports glasses

uvex sportstyle RX frames are equipped with high-definition (HD) prescription lenses with the latest free-form technology for optimum visual comfort. These lenses made of polycarbonate or Trivex™ guarantee the highest level of protection and maximum performance for a wide range of sports.

Formación sobre EPI individuales en la uvex academy

Nuestros seminarios de uvex academy permiten a los asistentes convertirse en la persona competente en EPI individuales de la empresa hasta que estos se hayan implementado.

uvex x-pertblog: el blog desarrollado por expertos en seguridad laboral para expertos

Aprenda aún más sobre nuestros productos y tecnología con ayuda de interesantes entradas en nuestro blog. Hable con expertos e intercambie experiencias.